CPP and PP Cartridge Filters

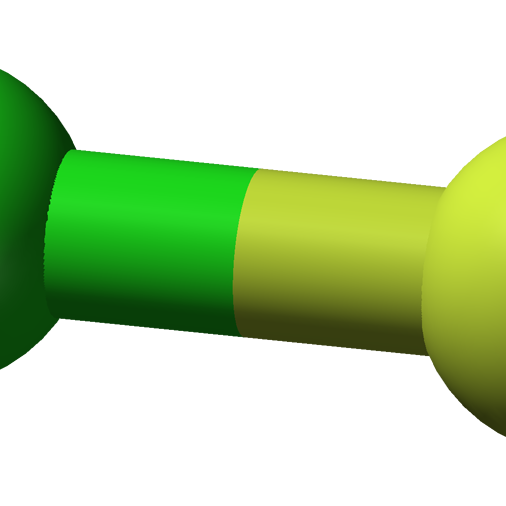

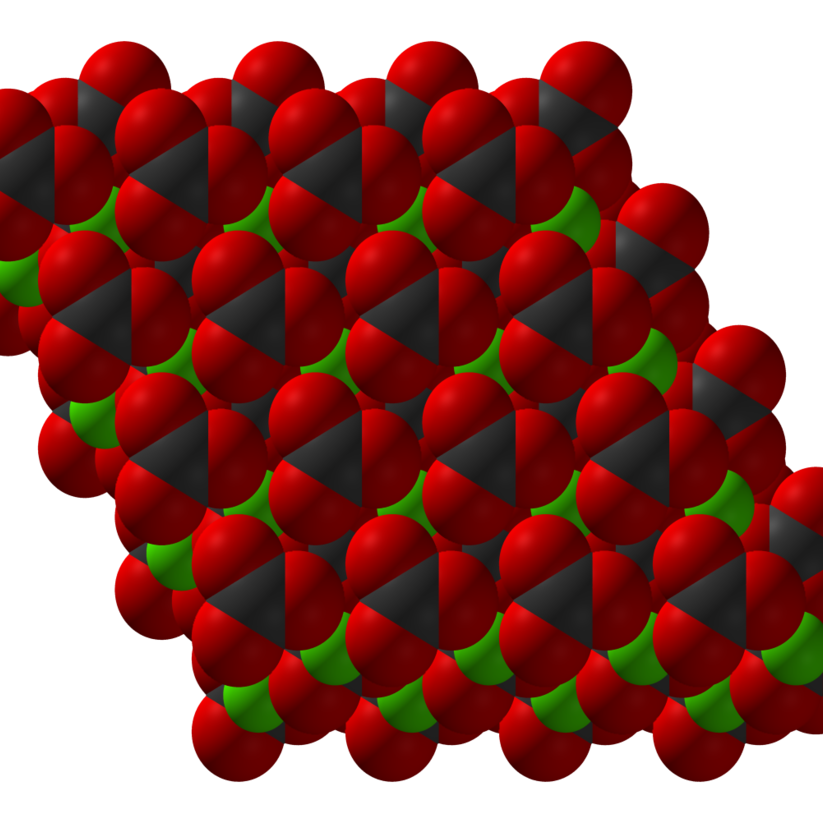

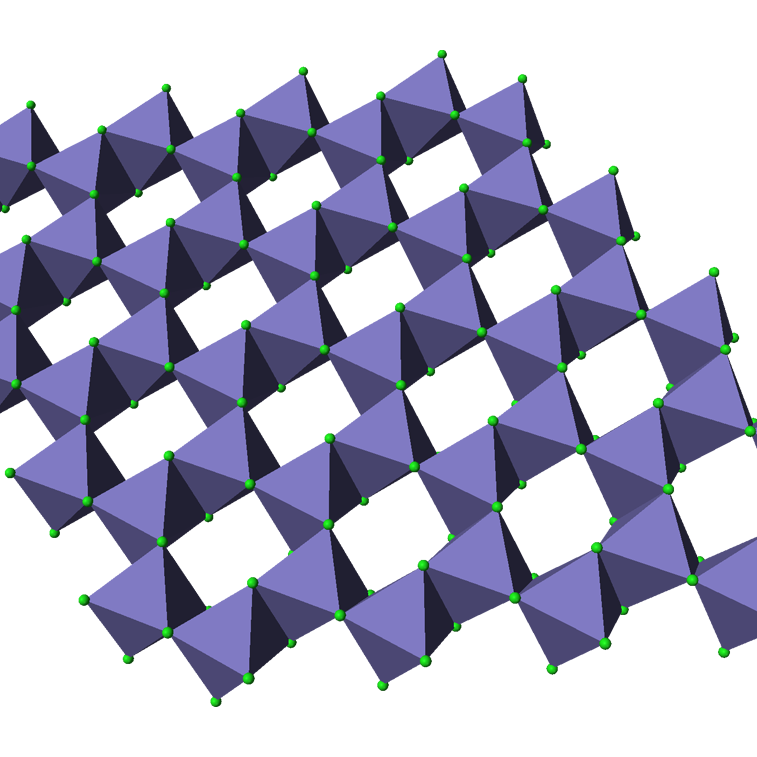

MELT-BLOWN polypropylene cartridges with

benefits in high-efficiency filtration.

- Standardization of the production with dedicated software for every stage of the process.

- Thermal insulation at controlled temperature.

- Certified raw materials.

- Full automation of the production line, from raw material loading to finished product packing.

- No direct human intervention, no contact with the product: total hygienic safety.

- Highest productivity.

- Quick delivery.

- Flexibility of the production line.

- Customized and OEM products.

The range:

CPP “melt-blown” smooth, filter rates 1, 5, 10, 25, 50 micron, heights 4”, 5”, 7”, 10”, 20”, 30”, 40”, 50”, 60”. SX, BX, AX, CX models (and other end-caps configurations).

Outer diameter: 56 or 62 mm (2.2” or 2.5”).

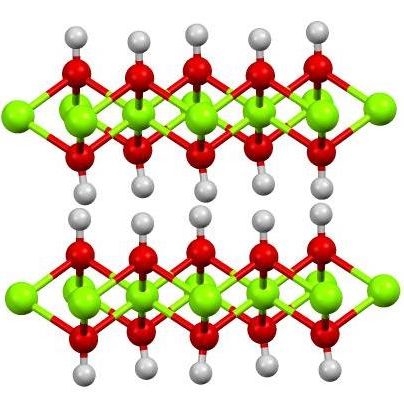

CPP-IC models with inner core.

CPP-IC/E models with inner core and end-caps.

PP “melt-blown” grooved, filter rates 1, 5, 10, 25, 50 micron, heights 10”, 20”. SX, BX, AX, CX models (and other end-caps configurations).

Outer diameter: 56 or 62 mm (2.2” or 2.5”).

PP-IC models with inner core.

PP-IC/E models with inner core and end-caps.

Max working temperature: 80°C (176°f).